I’m looking forward to sharing a preview of my upcoming book, Flatlined: Why Lean Transformations Fail and What to Do About It, at the 2018 Lean Accounting & Management Summit.

I’m looking forward to sharing a preview of my upcoming book, Flatlined: Why Lean Transformations Fail and What to Do About It, at the 2018 Lean Accounting & Management Summit.

Will you be there? Be sure to see my mini-keynote on Friday, September 21st. I’d love to hear your story of flatlining on Lean.

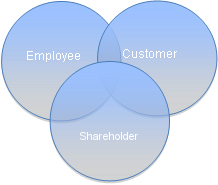

The Lean Trilogy characterizes the equilibrium that needs to exist between three primary stakeholders: the Employee, the Customer, and the Shareholder. If the requirements of these three groups are not met, the Lean Transformation will fail.

The Lean Trilogy characterizes the equilibrium that needs to exist between three primary stakeholders: the Employee, the Customer, and the Shareholder. If the requirements of these three groups are not met, the Lean Transformation will fail.