Introduction

I have seen hundreds of companies attempt to transform their business through the application of Lean philosophies and methodologies. Most of these businesses had initial success but eventually “flatlined” in their operating and financial metrics. The reasons for this are many, however, this article focuses on the primary root cause of false starts and failed transformations.

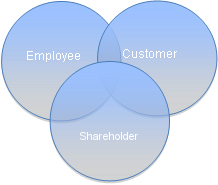

What is the Lean Trilogy?

The Lean Trilogy characterizes the equilibrium that needs to exist between three primary stakeholders: the Employee, the Customer, and the Shareholder. If the requirements of these three groups are not met, the Lean Transformation will fail.

The Lean Trilogy characterizes the equilibrium that needs to exist between three primary stakeholders: the Employee, the Customer, and the Shareholder. If the requirements of these three groups are not met, the Lean Transformation will fail.

I recently spoke with a rather large financial institution that started a transformation quite a few years ago. They were speaking with me to gain my perspective regarding their path forward after a rather failed attempt to cut costs. Their primary focus for doing a Lean Transformation was to take cost out of the business thereby improving profitability. As I listened to them describe their situation, they used the word “cost” over a dozen times as the primary objective. Never once did they mention the customer or their employees. The person I spoke with reported to the CFO, which further reinforces the fact that they have a cost mindset to satisfy shareholders, and rarely considered their customers and employees.

This particular company stated that cost cutting is one of the CEO’s main initiatives and that they were looking for someone to lead this transformation. The person they were looking for would report to the person who is in charge of Lean for this particular company. I told them that they already have the person in place that should lead the transformation, the CEO. They continued to insist that the CEO is committed. I told them, “Who wouldn’t be supportive of lower operating costs?” Is your CEO and leadership team willing to satisfy other stakeholders, namely Customers and Employees? They responded by saying “Well of course.” I had my doubts.

The tone for a Lean transformation needs to be set from the very top of the organization. This is exactly what Art Byrne did at Wiremold. Byrne, A. (2013) The Lean Turnaround. McGraw-Hill. The CEO must not only verbalize his commitment to the Lean Transformation, he must show it in his actions. Art Byrne talks about participating on Kaizen teams, attending Kaizen report-outs, self-education and even leading a Kaizen event. If the CEO delegates away his responsibilities to a staff position within the company, the Lean transformation will stall and eventually fail. The CEO must be as committed to the process of the transformation as he is to the results! Let’s take a look at the three stakeholder groups.

Employees

Many seasoned Lean practitioners that I have encountered view Lean as a set of tools and methodologies and do not fully comprehend that a Lean transformation is all about people. Understanding the WIFM factor (What’s In It For Me?) is crucial in gaining employee buy-in and support. Employees’ attitude toward their superiors, company, customers and work need to be a positive force that can be aligned to the goals of the organization. Processes must be designed so that ordinary employees can succeed in meeting the organization’s operating and financial goals. If organizations put as much focus and effort into designing world-class processes as they do in obtaining top talent, they would find their journey to world-class paved with rich rewards.

Many seasoned Lean practitioners that I have encountered view Lean as a set of tools and methodologies and do not fully comprehend that a Lean transformation is all about people. Understanding the WIFM factor (What’s In It For Me?) is crucial in gaining employee buy-in and support. Employees’ attitude toward their superiors, company, customers and work need to be a positive force that can be aligned to the goals of the organization. Processes must be designed so that ordinary employees can succeed in meeting the organization’s operating and financial goals. If organizations put as much focus and effort into designing world-class processes as they do in obtaining top talent, they would find their journey to world-class paved with rich rewards.

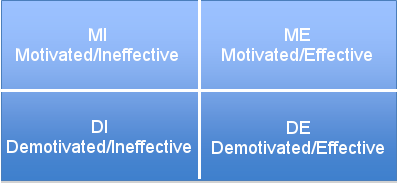

Employees typically fall into one of four categories:

The rate of change and the Continuous Improvement (CI) process will have an impact on people. It has the potential to motivate or demotivate and employees will oscillate between effective and ineffective as they are going through the learning process. Leaders must have tolerance and allow employees to make mistakes, always focusing on the process and not the individual. A well though out process will not allow for errors. People in general want to do a good job and working in an environment where problems are minimized has a direct impact on the motivation and morale of the employee.

As leaders, we want all of our people to be in the ME quadrant. As employees oscillate between ME and MI, leadership must provide air cover and encourage, recognize and reward those employees with the will to make positive change. Ineffective employees must be provided the proper training to succeed.

Employees in the DI quadrant need to either change or leave the organization. You will find that DI employees are not only found in the rank and file, but in all levels of the organization from the CEO suite to the janitor. It has been our experience that these naysayers represent about 10% of the organization. Employees in the DE sector need coaching to get them motivated. Studies have been done that correlate the level of satisfaction with participation in Kaizen events. The higher the involvement in Kaizen events, the higher the level of job satisfaction and morale.

I have seen this backfire, however. A Vice President of a midsized manufacturing company attended a Kaizen report-out on a Friday afternoon. The team made great progress, however the VP second guessed the team and told them that they should have done this and that. The team was totally demoralized. Subsequent Kaizen events were not met with the level of enthusiasm required to significantly change the organization. This Vice President eventually failed at his job and was replaced.

What happens when a Kaizen team reduces the headcount required for a particular work area? Are the employees laid off? Are they reassigned? The joke in the marketplace is that LEAN means Less Employees Are Needed. Unfortunately I have seen companies make the mistake of tying headcount reductions to the Lean Kaizen process. How can you ask for employees ideas then lay them off when they “Kaizen” themselves out of a job. How much success will you have with subsequent Kaizen efforts? Having a game plan in advance is crucial. Some companies, like Wiremold, had a No Layoff Policy as a result of Lean. They opted to reassign and retrain workers, insource where possible and place excess headcount on Kaizen improvement teams. Of course, as there was attrition, those employees did not need to be replaced. However one must think about Lean as a growth strategy. I call it “Profitable Growth through Operational Excellence.” As your quality, lead-times, delivery and overall value proposition improves, the Sales force should be able to leverage this operating excellence into profitable growth. This needs to be a part of any Lean strategy. In doing so, the excess headcount will take care of itself as the company profitably grows.

Customer

We hear companies focus on the “Voice of the Customer” (VOC). Many times, companies make the mistake of thinking they know how to satisfy the customer without ever asking what is important to their customers.

In my early days as a General Manager of Asian Business, my team was delivering 100% on time with 100% quality. When I went to Japan, I expected my customer to give me accolades for such excellent performance. Upon our visit, we were told that we ranked 106th out of 110 suppliers. What we didn’t realize was that we were being graded on our responsiveness to their various inquiries and requests. Because of the 12-hour time difference between the East Coast and Asia, we were always delinquent. Lesson learned: Do not assume you know what is important to the customer! Ask him!